01Research and innovation ability

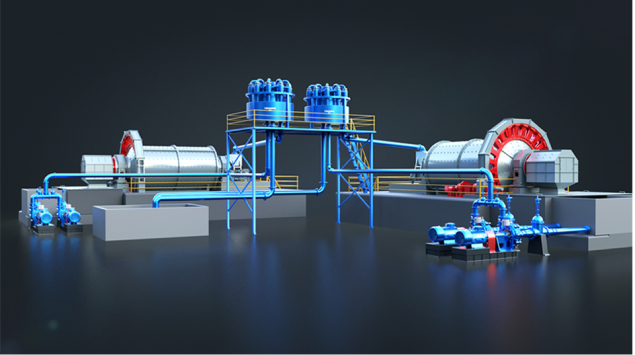

Our company has strong design and development capabilities, and can customize and technically upgrade various slurry pump products.

At present, we have four ceramic pump research centers dedicated to making up the technical gaps in high-wear-resistance pump products. Our company follows the international advanced design theory, adopts new special ceramic materials, standardizes the production process, improves the manufacturing accuracy, further enhances the reliability of the products, and has created new products and new technologies with independent intellectual property rights. Our pump products have a number of technical patents, which are reliable, durable, efficient and energy-saving, and have created significant benefits for enterprises and society. Now our company has four series of nearly 100 models of industrial pump products, which are widely used in factories, mines, power stations, metallurgy, chemical industry and urban and rural water supply and drainage and fire extinguishing systems, and are favored by users at home and abroad.

_副本.png)